At A Stand Still

Once I figured out that the marks not lining up wasn't that big of a deal after all, I felt good about following the example that Jay Brown outlined in one of his FEPOWER posts.

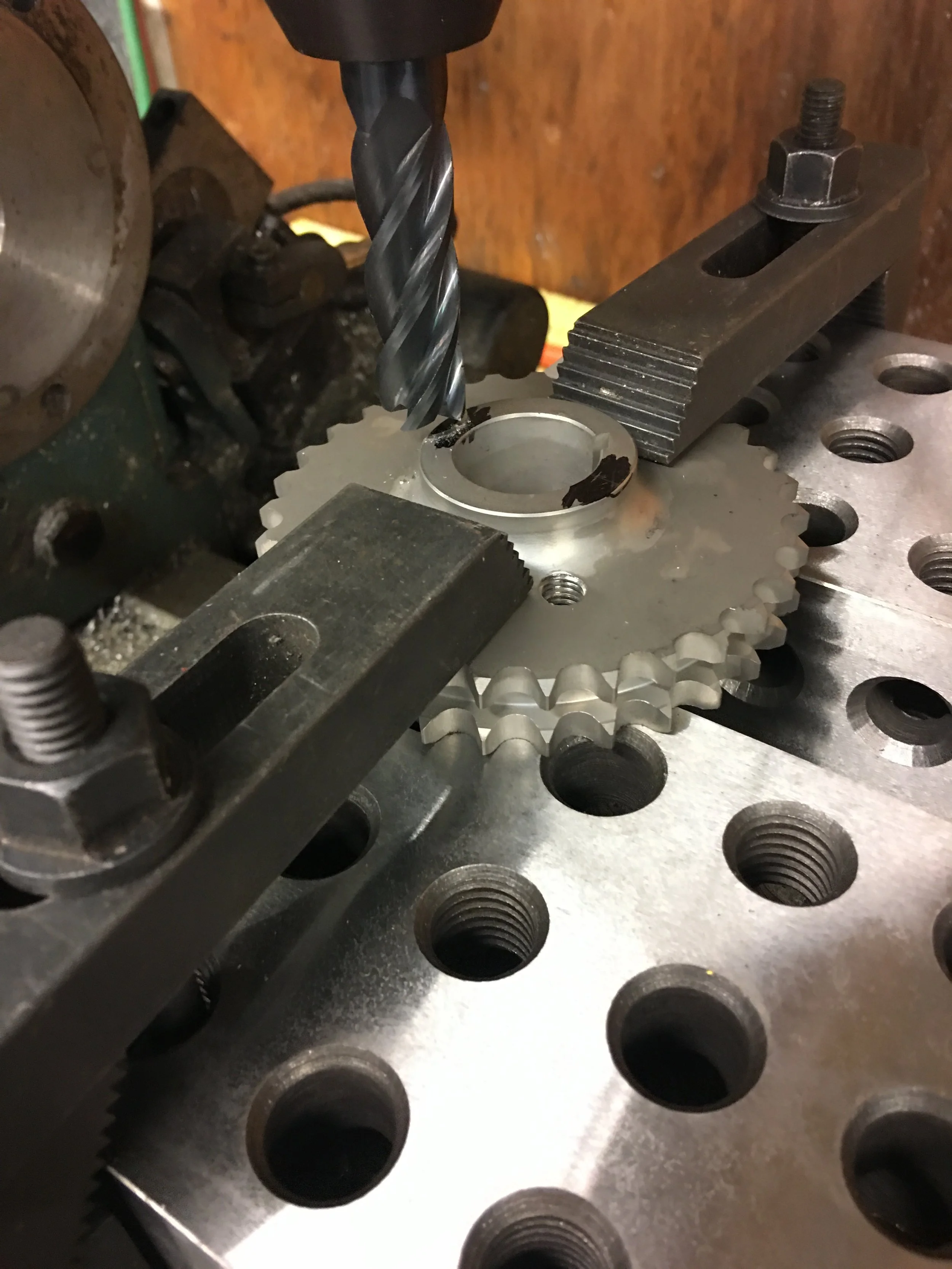

I started off strong using my mighty Smithy work station

I got the slugs welded in a did a bad job of it so I ain’t showing that.

I decided against using shoulder bolts like Jay did primarily because of a difference in design of the Robert Pond gear set I have, compared to the Paul Munro gears Jay used.

I decided I would not do slick and fancy and settle for caveman simple… If a caveman had power tools.

After welding the cam drive sprocket, It was drilled with a 1/4” cobalt drill bit. It was at this point I decide to forego the bolts and use metal bar stock instead.

I had some 5/16” bar stock. If I’d had some 1/4” I would have used that instead since that’s the size hole I started off with.

5/16 bar stock isn’t really 5/16” in diameter. It’s a tad smaller so I ended up using an “N” drill bit which gave me an interference fit. I plan to stake the metal once everything is pressed together to ensure that the pin stays in place.

With my press fit test a success, I thought it best to put both sprockets on the stub cam and use the cam drive sprocket as the jig to drill the primary sprocket.

The plan was working until I noticed that if I let the drill bit to keep boring down, it was going to cut into the cam stub journal.

I made the decision to start drilling each hole but stop way shy of coming out the other side. I would then disassemble the cam stub and then finish drilling the primary gear by itself. Doing it this way would also allow me to thoroughly clean all of the metal chips off of both sprockets and the cam stub before pressing everything back together.

The cam drive sprocket has two threaded holes in its face. If you find the proper size bolts to thread down into these holes, this is how the front sprocket is removed from the cam stub and it works quite well.

The Primary sprocket seemed like it would be easy to press back off of the cam stub.

As I was attempting to press the sprocket off, a little voice said that I should support the sprocket closer to the center of the hub. As I’m thinking this I continue to pump the handle on the press. I see the sprocket flexing and before I finish thinking that this is a bad idea, I hear a “POP”.

I freeze and my head drops in shame. I know I messed up.

I thought I cracked one spoke but it turns out I cracked two of them.

Like shutting the gate after horses have escaped, I grab a piece of 1/2” plate I bought for another project and cut an 2 1/8” hole in the center of it. The cam stub journals just barely clear the sides of the hole but they do fit without scraping and the sprocket has just enough of a lip over hanging the journal so it’s supported solidly on the plate.

If I’d taken the 15 or 20 minutes it took me to find the plate, get the hole saw and then cut the hole, I would not be looking at the cost of a new sprocket.

Luckily Doug Garifo and Precision Oil Pumps had the parts delivered the day I ordered a new sprocket.

If you recall, the heads I bought have larger than standard combustion chambers. I don’t want to mill the decks to get the chambers down to spec, I have future plans that will benefit from the larger chambers so for now, the best compromise is to go with a .027 thick head gasket which will get me to a static CR of 10:1. Unfortunately, Cometics doesn’t have these sitting on a shelf in their warehouse. This is a freaking 427 sohc cammer, you get used to things not being readily available. The gaskets will take approximately 6 weeks to arrive. 5 weeks to build them and one to deliver.

I had planned to pull the short block apart for two reasons. One is to check to make sure that all of the oil passages are clear, remember the heads? and the other reason is so I can clean all of the white grease out of the piston ring grooves. The grease is there from when I measured the piston dome CC’s. Before I could start that though, I sliced a finger open on my left hand. If I had cut the back of the finger, I would have hit the bone but since it’s the front that got cut, no bone, just a lot of blood.

So I’m pretty much without a left hand for several days while the finger heals. Where the slice is, it isn’t possible to lift anything without causing the slice to start bleeding again.

So here I am, just sitting and waiting for nature to do it’s thing and heal the cut finger.