Pulley Ratio Mix Up

While writing the post about matching up pulleys, I had to go back and look up the proper water pump to crank pulley ratio.

I can’t explain why but I had it in my brain that the water pump is supposed to spin a little slower than the crank.

It became a bit troubling when the newest search revealed my faulty assumption and that the water pump should be spinning the same speed as the crank or even a little faster.

Memories flashed by of the annoying search to find the current set of pulleys.

Finding the desired diameter isn’t really that hard since many places list the diameter of the pulleys being sold, it’s the depth of the pulley that is not listed most of the time.

In my earlier post, I talked about making my own spacers to adjust the depth of the crank pulley. I really don’t know if this is a legit move but I bought a single V pulley that came with a spacer, so why not use the same technique to adjust the depth of any other crank pulleys?

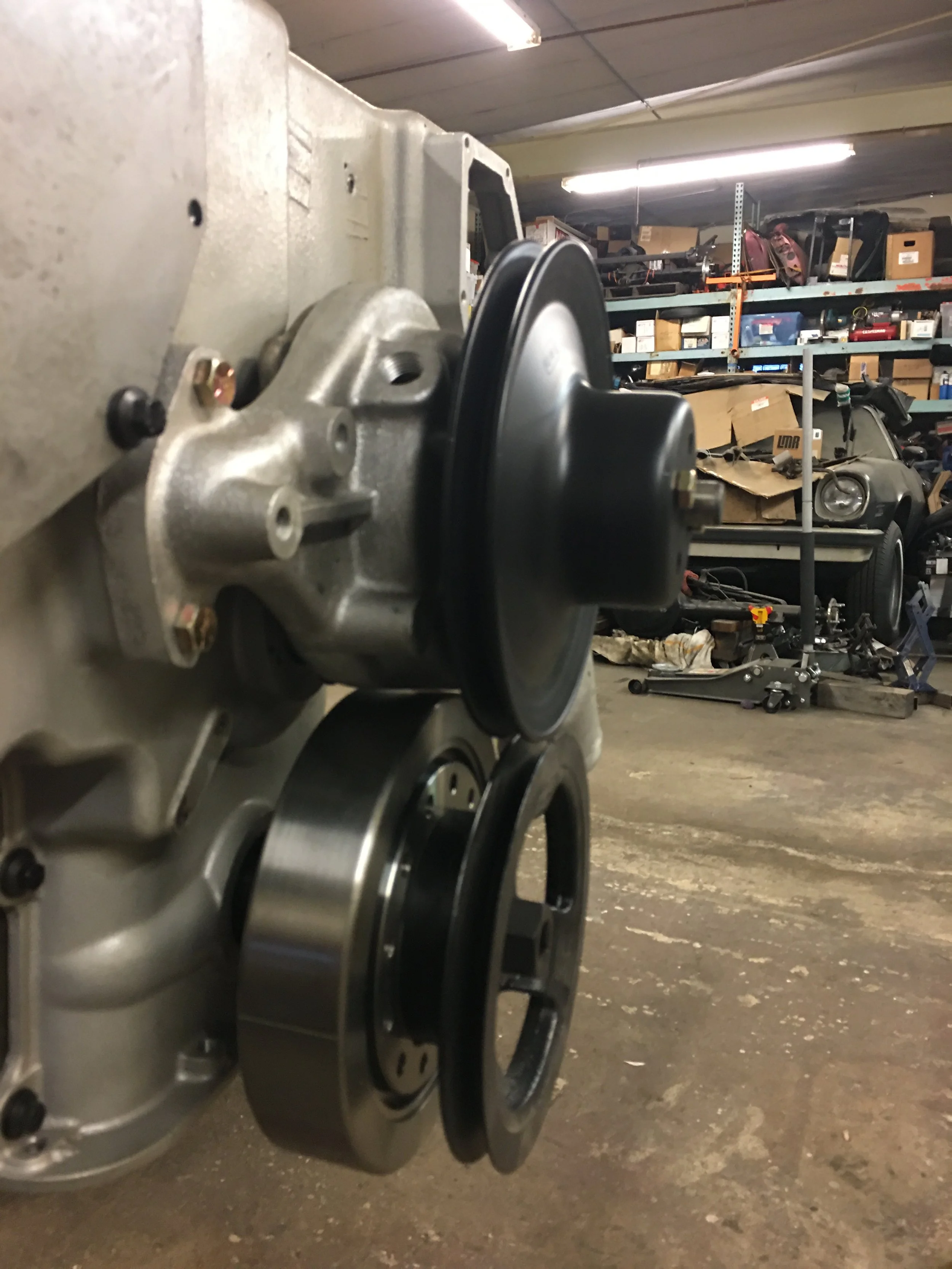

The crank and spacer combo were removed from the “SOHC parts” bin and bolted to the mocked up engine. I’m not thinking of future 2 V pulleys, I’m only thinking of finding a pulley for the water pump and right now, what I have is a single V crank pulley and that’s what will be reference for the entire system.

With this being my first Ford engine, I don’t have a box of pulleys from previous projects sitting around and I definately don’t want to wind up with one after this search.

I had the pulley from the 302 engine and it was way too deep. After that it was some trial and error with eBay finds.

Some measurements were taken and I came up with a rough depth for a pulley I think would work with my “Cammer Pulley”.

I found this site to be pretty helpful. Its a site called Mustangtek and it has a listing of pulleys used by Ford. It appears to be a work in progress but it gives Ford part numbers, description of pulleys, years used, engine, vehicle, etc. Not all of the information is complete but there is enough to help me in my search.

I only wasted money on a couple of pulleys to find one that aligned with the one on the crank.

The water pump pulley is 7 1/2” in diameter and has an inside depth of 2 3/8”. The crank pulley is a cast iron piece that is 6 5/8” in diameter.

Without realizing it, I had found a combination that also happened to work with the alternator.

I remember using a straight edge to check the alignment of all three pulleys by resting the straight edge into the V from one to another. I decided I would try to see if I could mount an AC compressor to this engine and if it is possible, I need a way to drive it so I went in search of a two V crank pulley.

Now it’s a couple of years later and I’ve realized my mistake about the drive ratio for the water pump. I dig the pulleys out of the box again and measure the diameters to confirm my screw up. Yep, screwed up.

I’ll need to find a pulley with a four bolt pattern, is no larger than 6 5/8” in diameter and is 2 3/8” tall

Can you believe it? On my very first outing I found a great option. It’s another eBay find and the pulley is for a 69’ Mustang GT 390 and it’s exactly the depth I need and it’s a little smaller diameter at 6 1/8” which is ok it seems. It’s very fortunate that the seller took pictures of the pulley as it’s being measured, Took out all of the guess work.

The seller has a store front called Northeast Classic Ford Parts if anyone has an interest for sources for their own Ford projects.

The pulley showed up a few days ago and the measurements checked out. It’s in pretty good shape but I think I’ll redo the finish. It’s been painted but it could be better.