12 years in the making

I should be attacking this portion of the build. It’s the whole reason for this project, for this blog. Well, mostly. It’s the reason once removed.

The dream has been the dream for 40 years and the first step in realizing that dream happened 28 years in when I acquired the cast iron block and heads for the 427 SOHC. 12 years later and I’m on the verge of putting an all aluminum 427 SOHC together.

A handful of years back the temptation was too strong and I had to do a build up of the engine. The aluminum block needed a lot of machine work to make it usable. The pistons I have wouldn’t even fit in the raw bored cylinders so the cast iron parts were used in my little build up.

The exercise was more than me just having to see this engine I’d been waiting on for so long in real life. I had to check to know if I had enough valve to piston clearance, degree the cams in, play with the 6 foot timing chain. Important stuff.

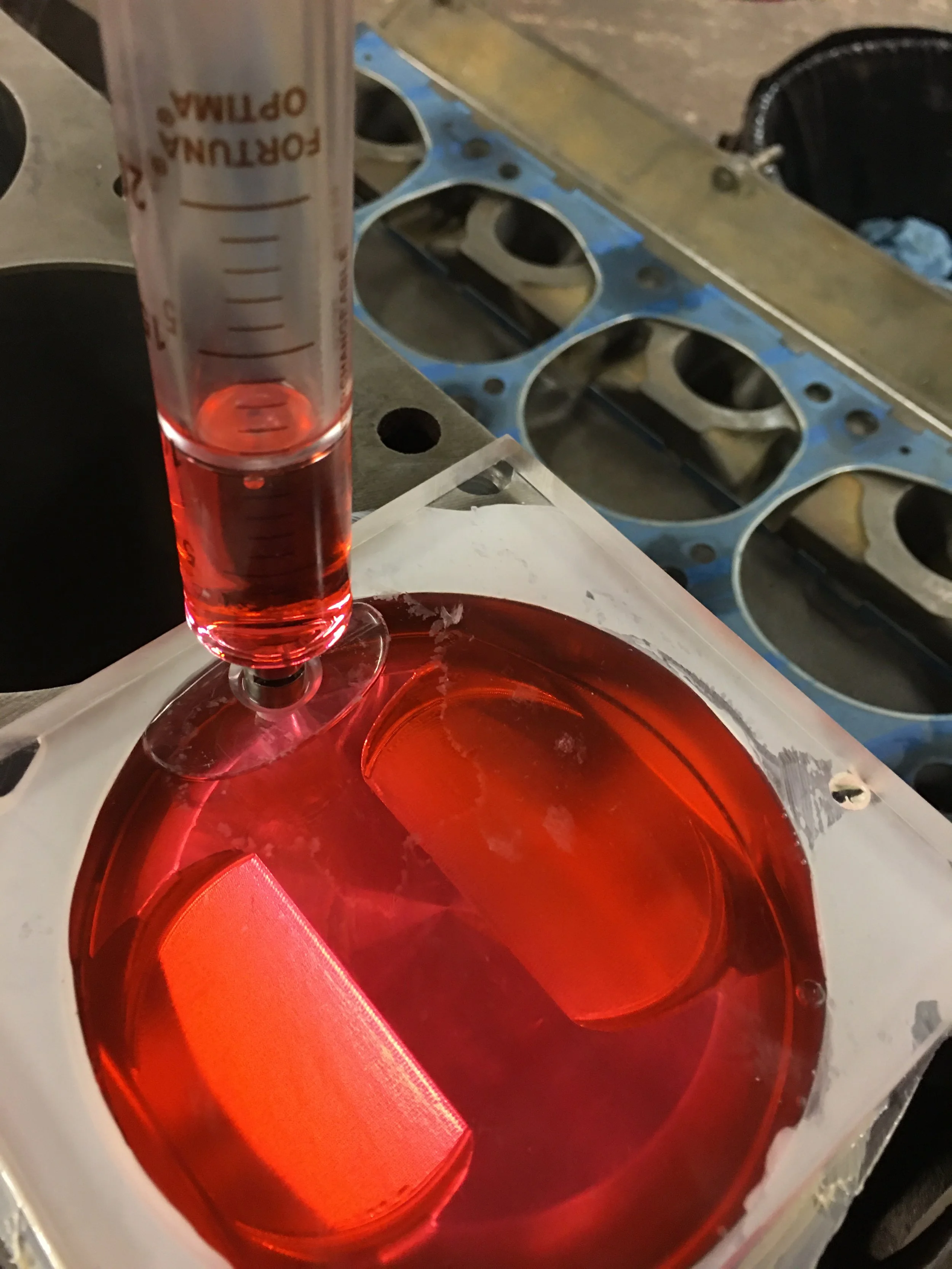

I had to see how everything fit together and if they would fit together. I also really wanted to know what the true static compression of the engine was. I bought 10.5:1 pistons but I started thinking I made a mistake with the compression. Maybe I should have gone lower. I was hoping that the piston company over sold their wares and that the compression was actually lower than the advertised 10.5:1. Only one way to verify anything is to measure the combustion chamber and the dome of the pistons and do some math.

I’ll go into the boring details in a later post but what I found was that the static compression was really 10.98:1. Essentially 11:1.

First I was hoping for less than 10.5:1 and now I find myself just trying to keep things at that compression.

Short of buying new pistons, the only way I can lower the compression is to go with a thicker head gasket. My initial selection was a Cometic .040 thick gasket. After doing some more math, I found that if I used a head gasket that was .066” thick, I could drop nearly a half of a compression point.

That was with the cast iron block though.

Now that the Mustang will be getting an aluminum engine, I can’t be certain that the numbers will be the same so I’ll be doing the whole compression test thing again. I’m kinda hoping that this block was cut with a oh so slightly taller deck height. It’s not really a good way to lower the compression but having the piston a couple of thousandth farther down the hole shouldn’t be too bad.