Alternator Bracket.

Now here’s a topic I never thought I’d get into. Nothing wrong with it but how much can you type about pulleys

Building an engine from scratch and a platform you’ve never dealt with before, a lot of stuff you need to buy goes through your head, I mean A lot.

Somehow, I was able to remember that I needed pulleys, sooner than later.

Like everything that’s needed these days, the search began on ebay. This was early on in my education on the 427 SOHC and I knew very, very little.

I found an ebay post for a 427 Cammer crank pulley. I bought it, it was delivered and then sat for years in one of the bins I had for “Cammer” stuff.

2019-2020? I wanted to put the engine together just so I could play with that long ass chain the engine is famous for.

I went through the build-up. I even practiced CCing the combustion chambers and the piston domes. I set the cam timing according to the Ford factory 427 Single Overhead Camshaft manual. No one uses those numbers but it’s good practice.

With the build-up, I finally had the engine sitting on a stand with the water pump and harmonic balancer on it. Two of the three devices that will need a pulley. Realizing the opportunity, I dug out my official Cammer crank pulley. I still need a water pump pulley. dammit.

Another shopping trip through ebay for a Ford FE 390 water pump pulley and $20 later, it was on it’s way.

For the record, an actual Cammer crank pulley is super rare. I found out that the pulley was originally sourced from a T-Bird engine which is just as rare. The earlier Fords had the pulley and balancer as one unit, or that’s how it looks to me. That’s what the Cammer had and that’s definitely not what I have in my parts bin.

I know matching pulleys can be a tricky deal so when the water pump pulley showed up, I bolted it in place and then mounted up the crank pulley which also included an aluminum spacer. I don’t know if this is proper but either way, the two pulleys actually lined up.

I dug out the alternator and the “Ford FE 360, 406, 390, etc” Alternator bracket and bolt kit I bought off of ebay, to see how these bits would bolt onto the engine.

A few weeks earlier, I went through the Ford 427 SOHC manual and wrote down every bolt and quantity that the book listed and went to the local hardware store so when it came time to bolt the alternator into place, I had the proper length fastener. Yay me!

The alternator bolted in fine. The alternator brace/mount fit as one would have hoped. The thing that wouldn’t go is the bracket that connects to a bolt on the water pump and down to the alternator. This is part of the adjuster or tensioner for the alternator.

The bracket is way too short, like, half the length. The only references I have is a picture in the Ford SOHC manual and a plastic model that Collin bought for me. I searched the internet for any leads including ebay.

I have no idea if this bracket was borrowed from another model or was it made specifically for the Cammer.

Reaching for straws, I dug out the alternator bracket for the 302 out of the Mustang. It was too short although the shape was promising.

After staring at the model and the picture from the manual, I could see similar shapes in the brackets I have and the unobtainium in the picture.

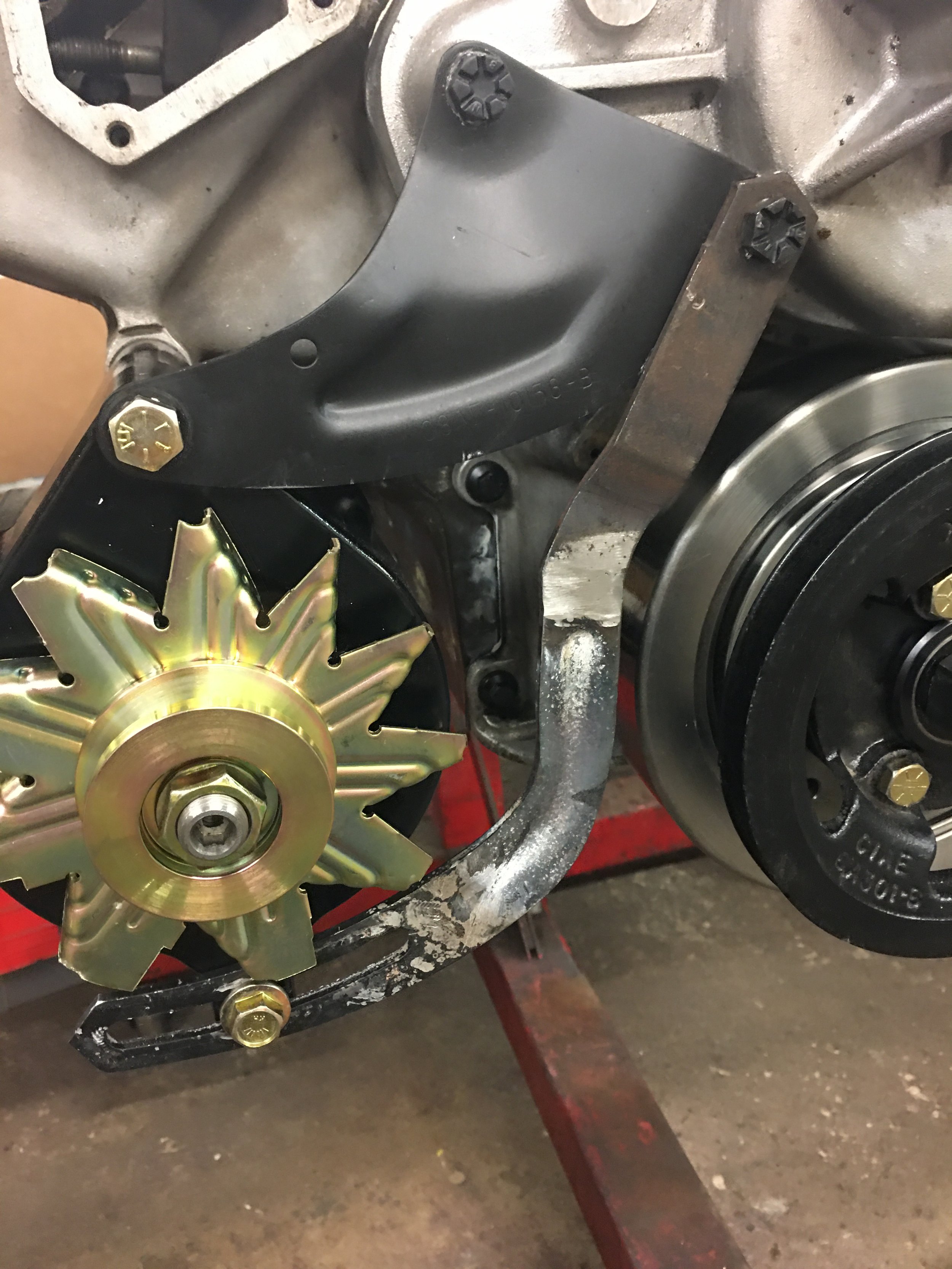

Without going into too much detail (too late) I ended up cutting and then splicing the two brackets together. A little bending on a makeshift metal brake and I had an approximate of the bracket I see on the model. Better yet, it works. A little clean up and a coat of paint and I have my alternator bracket.